CO2 Enhanced Oil Recovery Explained

Energy, especially crude oil-derived products, is an integral component of our daily life. Oil drives our economy in a variety of ways, from transportation to apparent goods like pharmaceuticals, plastics, and other elements that people use on a daily basis. Most Americans, on the other hand, have a poor knowledge of where oil comes from and believe that the bulk of oil imports come from the Middle East, but this is not true. In fact, domestic production is the largest source of crude oil in the USA and the country is the third largest producer of oil in the world.

In addition, the U.S. is the leader in technological advancement in petroleum production, with tertiary methods such as thermal recovery, gas injection and chemical injection being at the forefront of the oil production technology. During the primary phase of oil production, gravity, or natural pressure of the reservoir combined with artificial lift techniques such as pumps, drive the oil into the wellbore bringing it closer to the surface. However, only 10 percent of the original oil in the reservoir is produced during the primary recovery. CO2 EOR has been identified to be efficient in recovering residual oil from the reservoirs. Read on to know more about CO2 Enhanced Oil Recovery.

What is CO2 Enhanced Oil Recovery?

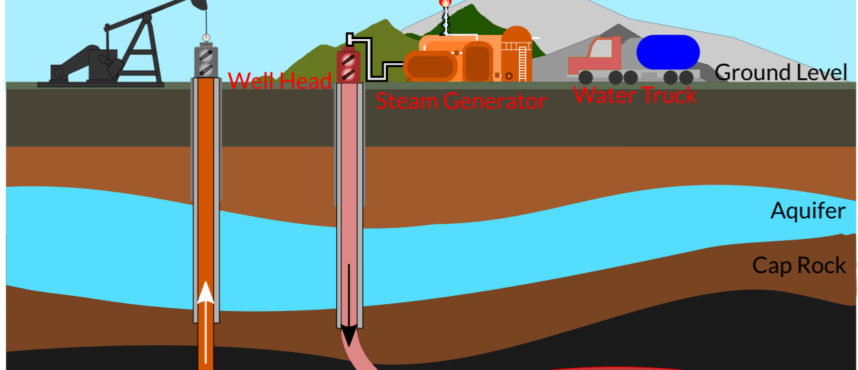

CO2 enhanced oil recovery is a process of obtaining crude oil from the pores of a rock by injecting Carbon dioxide into the subsurface to enhance oil recovery. The miscibility property of the oil determines the interaction of carbon dioxide and crude oil. During co2 enhanced oil recovery, carbon dioxide mixes with oil, helping it move through the rock pore spaces. This helps to recover more oil. Tertiary or enhanced oil recovery techniques (EOR) are easy-to-produce oil and offer more prospects for producing 30-60 percent of the original oil in the reservoir. EOR techniques involve three categories:

- Thermal recovery: Involves the use of heat such as steam injection.

- Gas injection: Uses gases like nitrogen, carbon dioxide (CO2), or natural gas.

- Chemical injection: May include the use of long-chained molecules known as polymers to improve the efficiency of waterfloods and to reduce the surface tension inhibiting oil molecules from flowing through. Chemical methods account for approximately one percent of EOR generation in the United States.

CO2 -EOR technique attracts most new markets because of its success in the oil production and development industry. While previous CO2-EOR developments only utilized naturally occurring CO2 deposits, technology plans have been developed to foster the injection of carbon dioxide derived from industrial processes.

How Does CO2 Enhanced Oil Recovery (CO2 EOR) Work?

How does injecting carbon dioxide into the rock pores help in moving crude oil out? CO2 has a couple of characteristics that make it ideal for enhanced oil recovery: It is miscible and less costly than other miscible fluids. CO2 blends well with oil improving its mobility and allowing it to flow more easily. The EOR process can be achieved using carbon dioxide through two methods: immiscible or miscible displacement depending on the temperature, oil characteristics, and reservoir pressure.

The Miscible Displacement Method

CO2 completely mixes with crude oil during the miscible displacement method through multiple or a single contact between the crude oil phase and the gas phase. The approach must be used at high pressure to ensure miscibility between the situ oil and the injected gas. The pressure at which miscibility takes place is known as minimum miscibility pressure (MMP). MMP is a crucial factor during the miscible CO2 flooding as the displacement efficiency is highly dependent on it.

Through multiple contacts, CO2 achieves miscibility. At this point, light hydrocarbons (low density, light-low carbon) are vaporized into the CO2 phase. With time, the gas phase is overwhelmed with vaporized light hydrocarbons, which eventually change the gas phase composition that ultimately becomes denser and heavier. The denser and heavier gas phase eventually condenses into the crude oil zone, resulting in crude oil density and viscosity.

As miscibility occurs between the injected CO2 and residual oil, the interfacial tension (IFT) between the gas and oil phase becomes zero. Therefore, the mixture is displaced as one phase from the pores of rocks to the oil wells. The miscible displacement method increases the overall displacement efficiency, promotes ultra‐low (near zero) IFT, minimizes residual oil saturation, and significantly increases overall oil production. The only downside of the miscible displacement method is that the process requires high operational costs.

Immiscible Flooding

Immiscible flooding is less effective than the miscible displacement method. Technically, the method recovers half of the oil that is recovered by the miscible method. During the immiscible flooding method, oil recovery is achieved through oil swelling, enhancing macroscopic displacement efficiency. The constant immiscibility of crude oil with CO2 is more favorable with light oil than the heavy oil reservoirs.

During this mode, CO2 and oil are not miscible and would not form a single phase. However, carbon dioxide dissolves in the oil resulting in swelling of the oil. This reduces the viscosity that will not only improve additional oil recovery but also enhance sweep efficiency. Carbon dioxide solubility in oil decreases temperatures and increases with pressure.

For improved recovery of heavy oil, co-injection of CO2 or injection of water as an alternative to gas is done through the WAG method. This helps control gas channeling, viscous fingering, and early gas breakthrough. The immiscible method enhances oil displacement efficiency and is mostly applied in light oil formations. The approach, however, is primitive, especially in heavy crude oil formations.

How is CO2 Used in Enhanced Oil Recovery?

Improved oil recovery approach using gas is also known as capillary number increasing processes. Carbon dioxide Is a tertiary recovery or enhanced oil recovery technique used to recover oil that was not recovered through the secondary processes. Through the process, oil from high-viscosity and depleted oil fields is recovered. Much of the carbon dioxide used for IOR operation comes from underground, and about twenty percent of the Co2 comes from natural gas.

This approach makes use of the energy that is generated because of the expansion of gas. The energy drives the gas in a reservoir which then forces the oil out of the wellbore. Depending on the fluid and rock properties, reservoir geology, well-pattern configuration, and timing relative to waterflooding, the CO2-EOR technique may use several recovery methods as described below:

Continuous CO2 Injection

This procedure necessitates the continuous injection of a specified amount of CO2 in the absence of any other fluid. To enhance gravity segregation, a lighter gas, such as nitrogen, is sometimes injected after the CO2. This method is used after primary recovery and is most suited for gravity drainage of reservoirs with medium to light oil, as well as reservoirs that are heavily water-logged or susceptible to floods.

Continuous CO2 Injection Followed with Water

Except for chase water, which follows the total injected CO2 slug volume, this method is identical to the continuous CO2 injection process. This method works effectively in reservoirs with limited permeability or reservoirs that are somewhat homogeneous.

Conventional Water-Alternating-Gas (WAG) Injection

In this approach, a set volume of carbon dioxide is injected in rotations followed by an equal amount of water. CO2 injection alternating with water minimizes CO2 channeling and helps ovoid the gas override, improving overall CO2 sweep efficiency. The approach is fit for reservoirs with permeability contrasts in different layers.

Tapered WAG

The approach is like the conventional WAG but with a gradual reduction in the injected oil relative to the volume of water. The primary focus of the approach is to approve carbon dioxide utilization. It prevents early breakthroughs of carbon dioxide and improves the efficiency of the flood.

WAG Followed with Gas

The approach is like the conventional WAG method followed by less expensive gas such as nitrogen after carbon dioxide slug volume has been injected. The approach utilizes the injected and gas resulting in increased oil recovery.

Why is Enhanced Oil Recovery Necessary?

Enhanced oil recovery is becoming an essential technique in global oil production because of several reasons. Enhanced oil recovery provides the only viable solution for recovering oil anywhere up to 80% of the world’s oil reserves. Primarily, the approach maximizes the oil reserves recovered, increases the recovery factor, and importantly extends the life of fields. The enhanced oil recovery method is ideal for companies looking to maintain their production and maximize their returns on older investments. With the new materials and technologies, EOR is proving to be the most viable way that is providing extra output in mature fields. From the above discussion, combined primary and secondary oil recovery methods can only achieve 20 to 40 percent of the oil to be recovered. A large amount of the potentially recovered oil is left in the reservoirs, necessitating the availability of suitable enhanced processes of oil from residual oil zones (ROZs). From the available EOR processes, CO2-EOR is the most widely used and one with the highest potential for additional oil recovery. If you need expert advice on EOR techniques to help boost your production of residual oil, Melzer Consulting is your trusted advisor. Our team of experts will help you screen and optimize your oil recovery project and guide you through the recovery process.

If CO2 is miscible with oil then there is a single phase. If CO2 is immiscible it still dissolves in the oil according to your explanation. In both cases the injected CO2 will be brought to the surface combined in the liquid phase with the oil and is not sequestered. Is this interpretation correct?

You’re correct in identifying that there are multiple mechanisms potentially at play depending mostly on CO2 injection pressure. A large portion of the CO2 does come to the surface with the oil and water, but it is immediately separated at the surface and recompressed for reinjection. The CO2 that stays in the ground is what displaced the oil and water and is effectively sequestered. New CO2 purchases are necessary to make up this volume. In total, for a given 100 units of CO2 being injected, recompressed, and reinjected, around 30% remains in the ground.

Now the next consideration is the source of the CO2. If it is from a naturally mined source, then you can’t really count this as new sequestration since it was moved from somewhere in the ground to another place in the ground. If the CO2 is sourced anthropogenically (like from a CO2 capture facility on the back of an industrial process) then you would consider the CO2 that stays in the ground as sequestered, which offsets the CO2 impact of the produced oil. It’s even more complicated than that, but I think I’m already going well outside the scope of your question. Also I’m not a member of this website, just providing some helpful info as I passed through.